The aim of the project is to explore the possibilities and limitations of spraying non woven natural fibers and bio-based binder composite for rapid on-site construction of low-cost tensile membrane structures. The project endorses human-machine collaboration both with high and low tech fabrication agents.

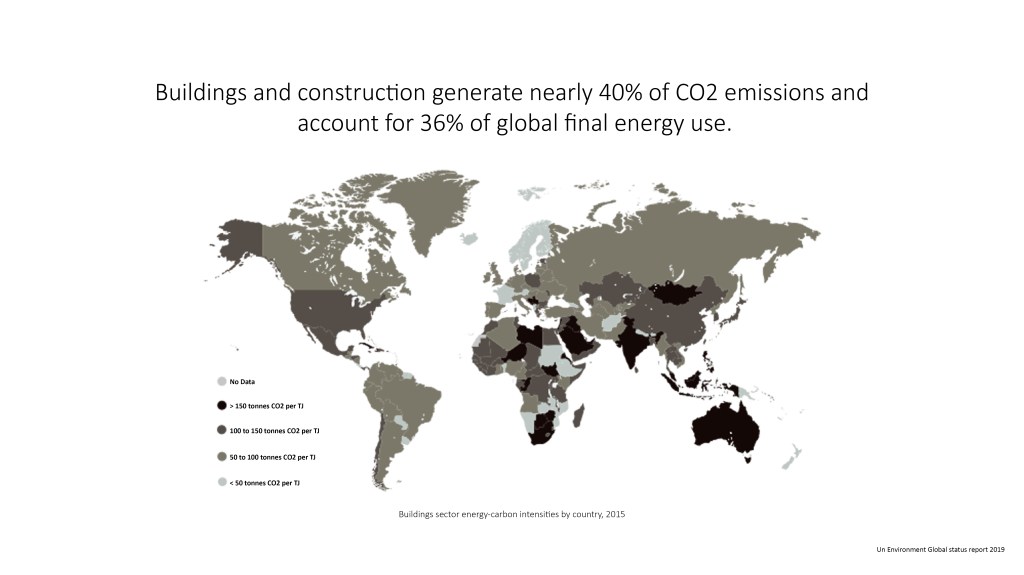

According to new research by construction blog Bimhow, the construction sector contributes to 23% of air pollution, 50% of the climatic change, 40% of drinking water pollution, and 50% of landfill wastes.

Can we Build?

Low Cost Sustainable Temporary

Permanent structures increasing carbon footprint, creating pressure on the environment, materials not being reused, by observing this aspect of architecture we came up with the base idea for this project.

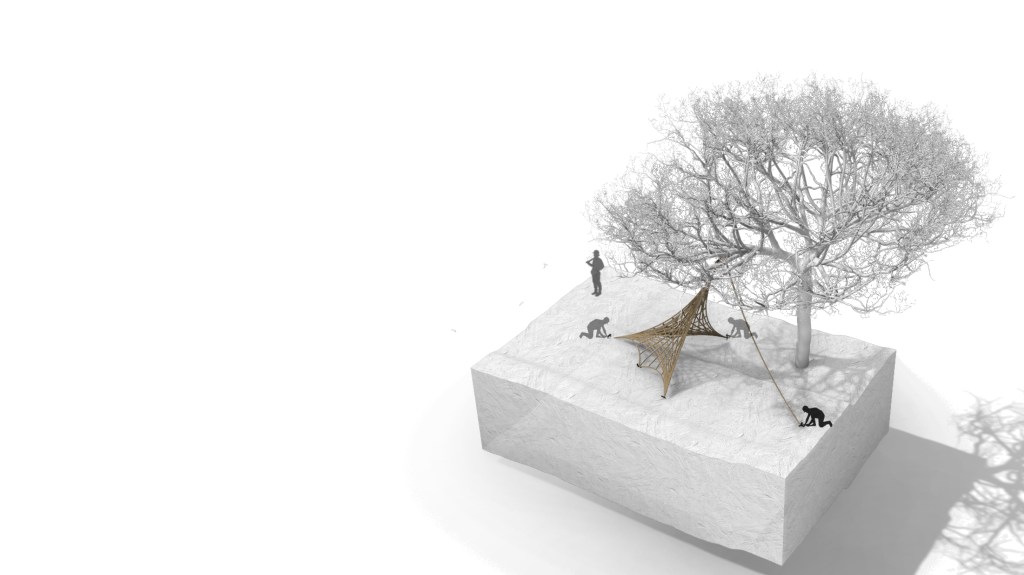

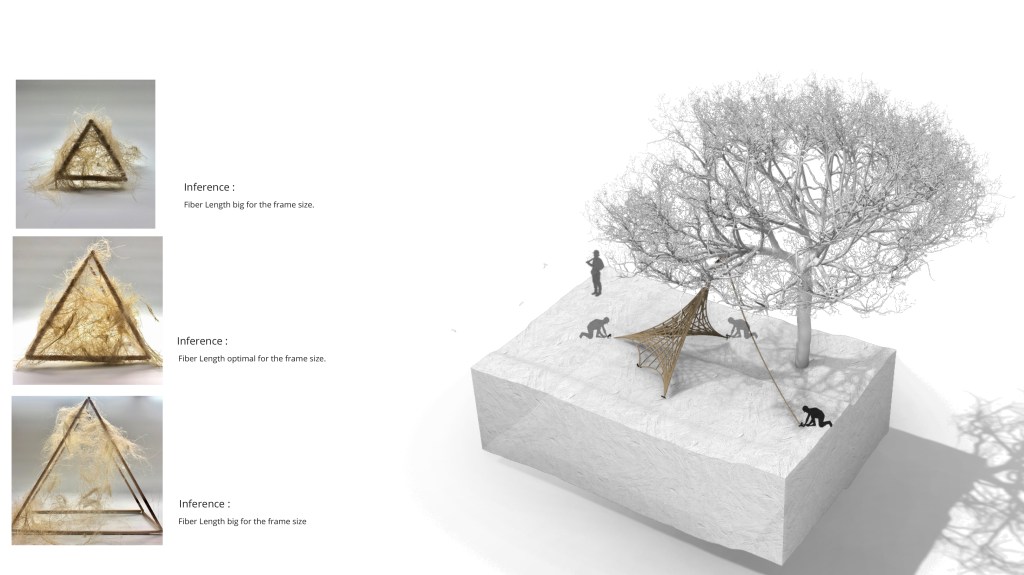

Fiber tangled is a project looking into spraying non-woven natural fibers and bio-based binder composite for rapid on-site construction of temporary low-cost tensile membrane structures. The project endorses human-machine collaboration both with high and low tech fabrication agents.

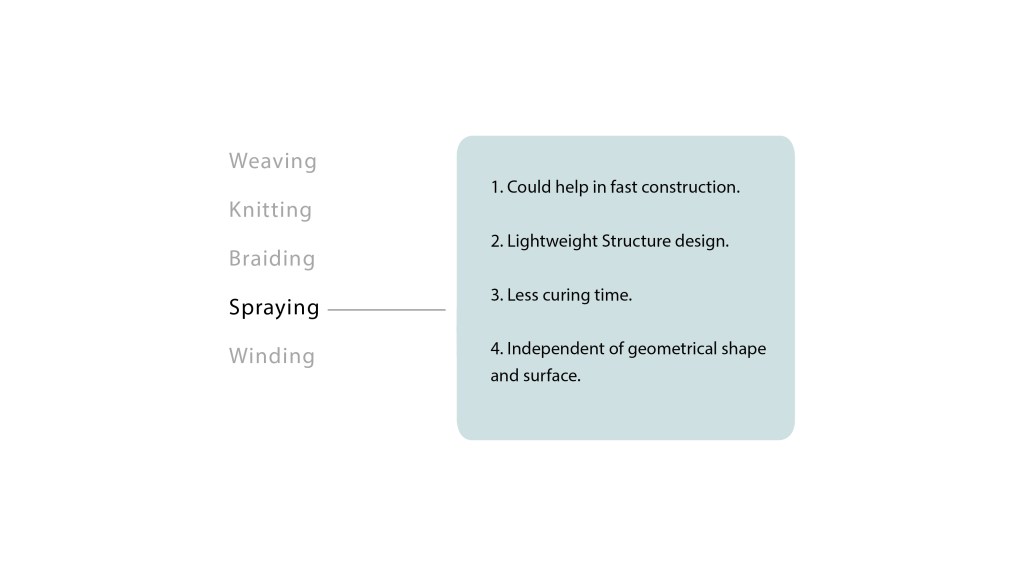

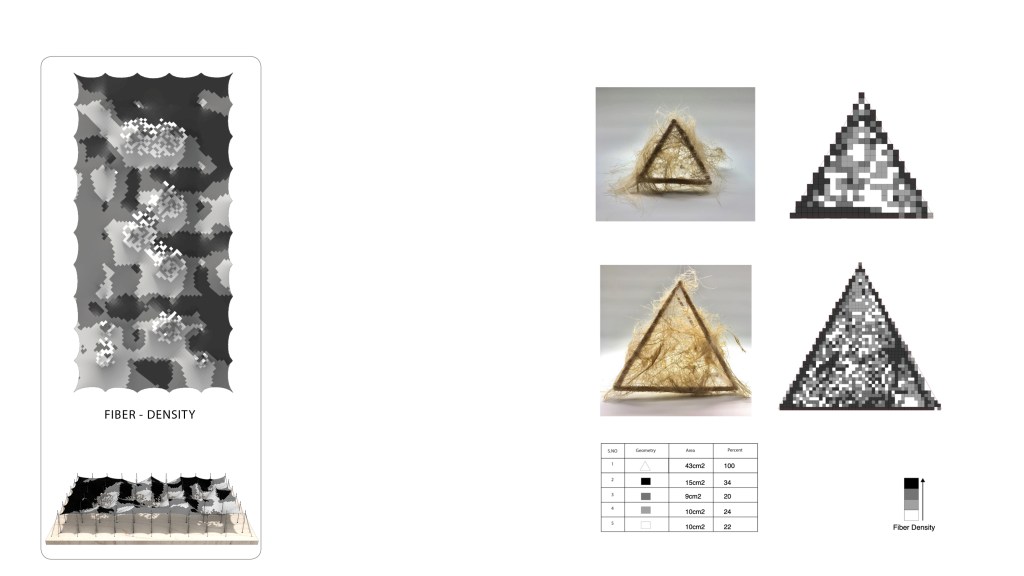

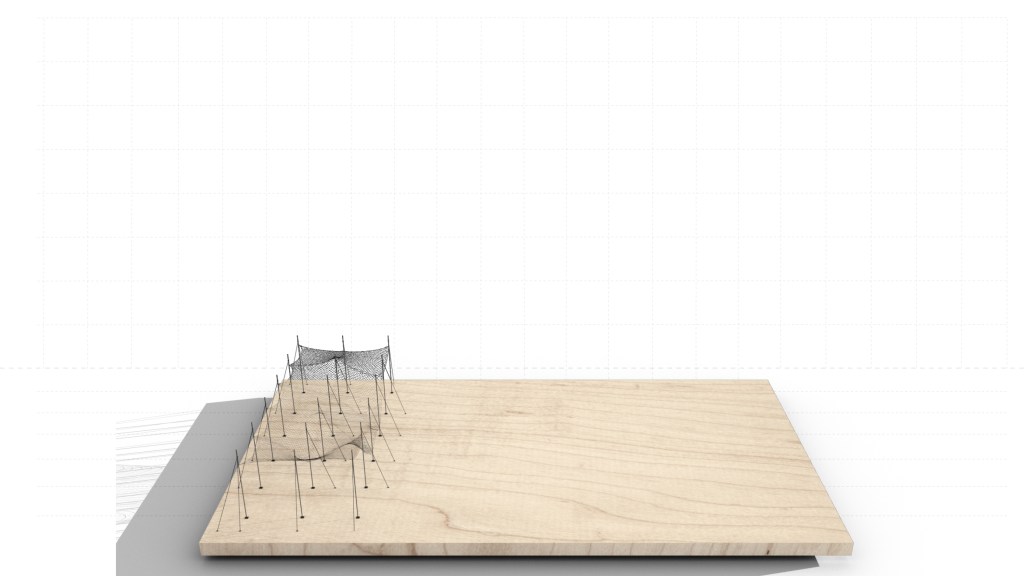

Spraying as a technique is chosen as it is a low cost and fast method to aggregate non-woven fibers along with a bio-binder to create a rigid membrane which is not preprocessed and can be done on site decreasing the construction time.

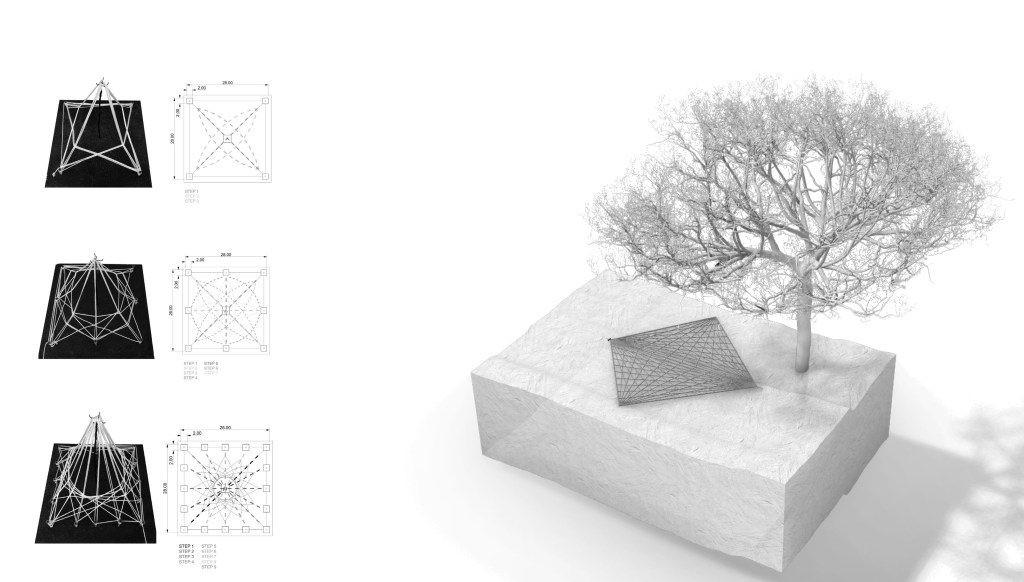

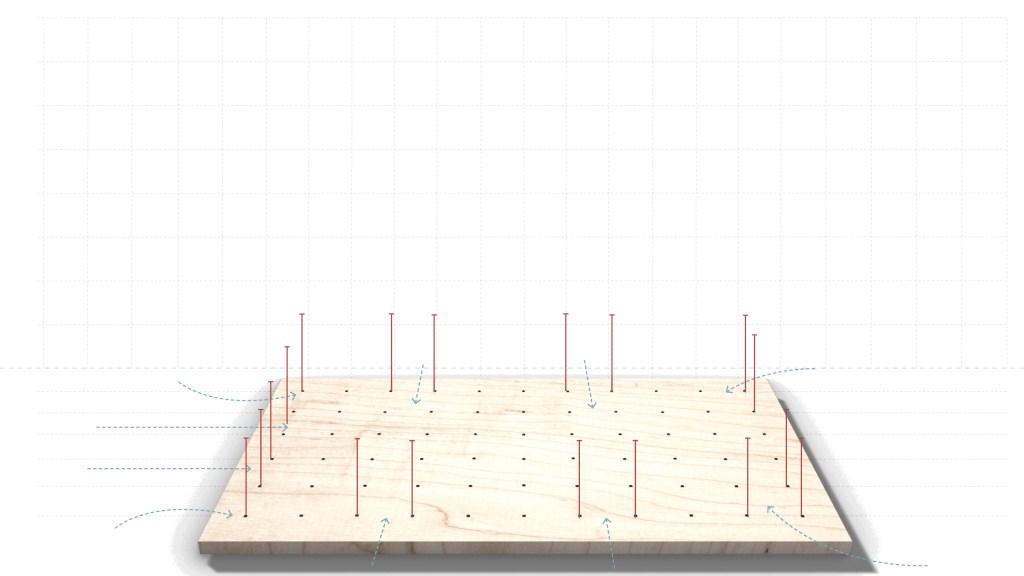

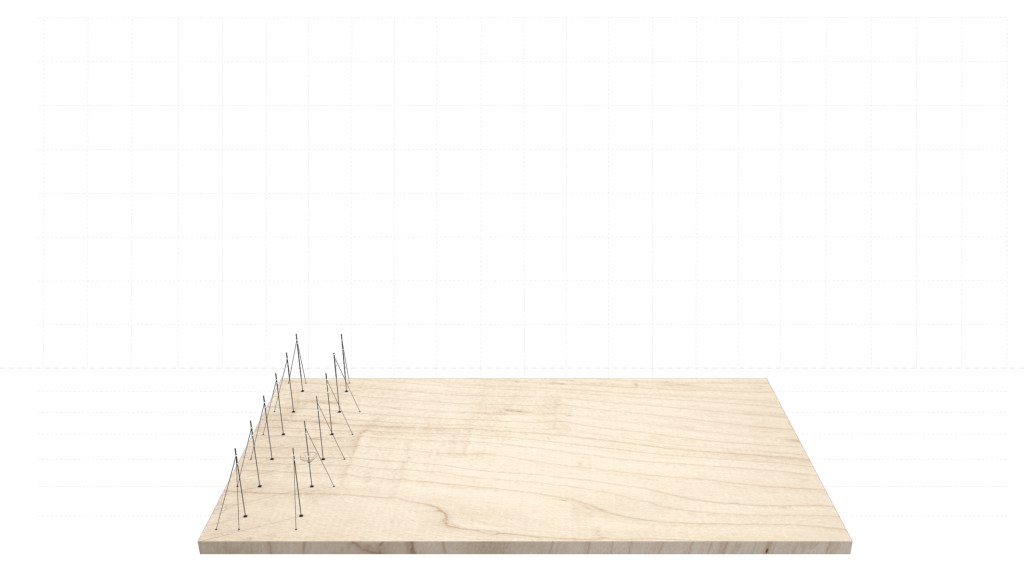

The fibers-binder composite is sprayed on a sub structure which can be constructed on site or could be pre-fabricated and installed during the construction process.

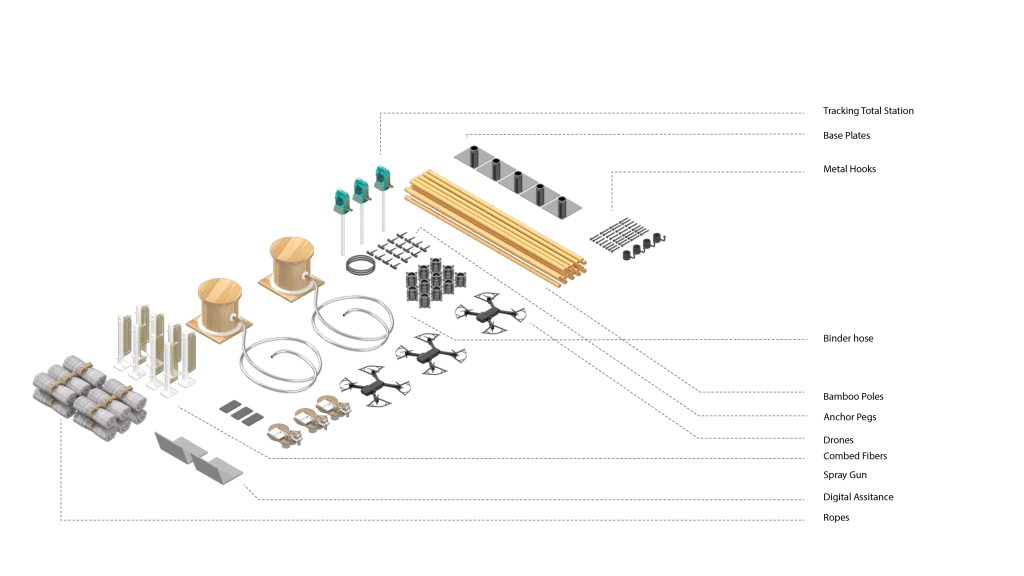

The Technique is scalable and can be used in various scales depending on the function which also relates to the technology involved in the construction process, as the complexity of the structure or the scale, high tech fabrication systems using aerial flying machines and/or mixed reality are established to ease the construction, the construction could be also done by a human carrying a backpack with certain kit of materials.

Matter

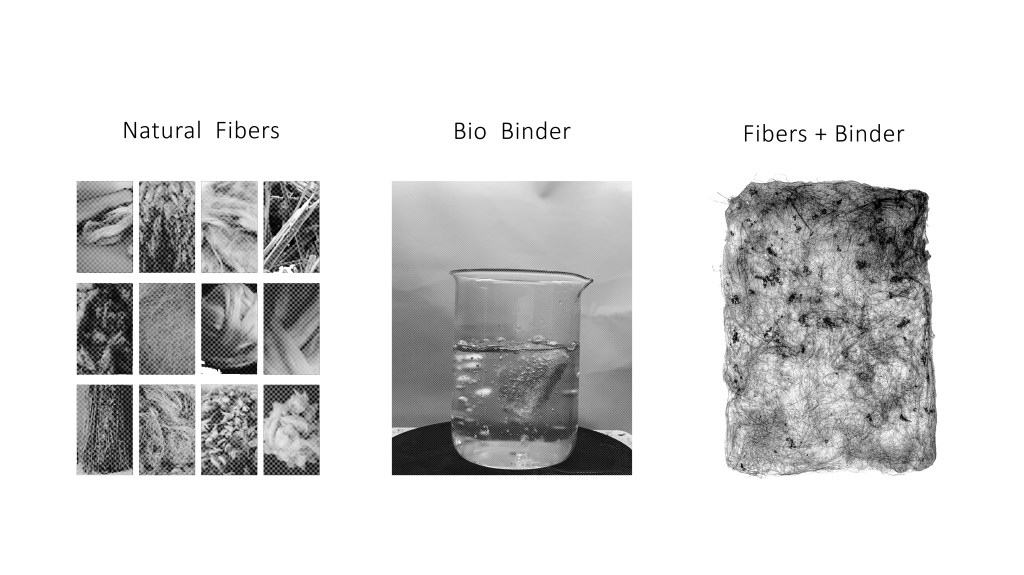

Natural Fibers

General Information

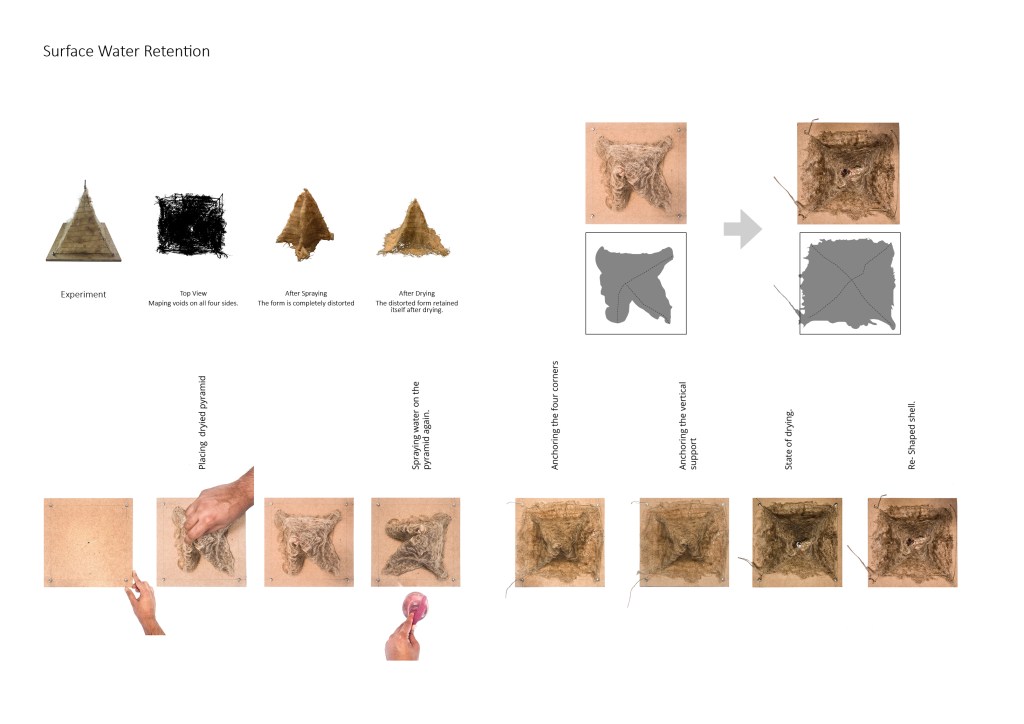

Material Behavior

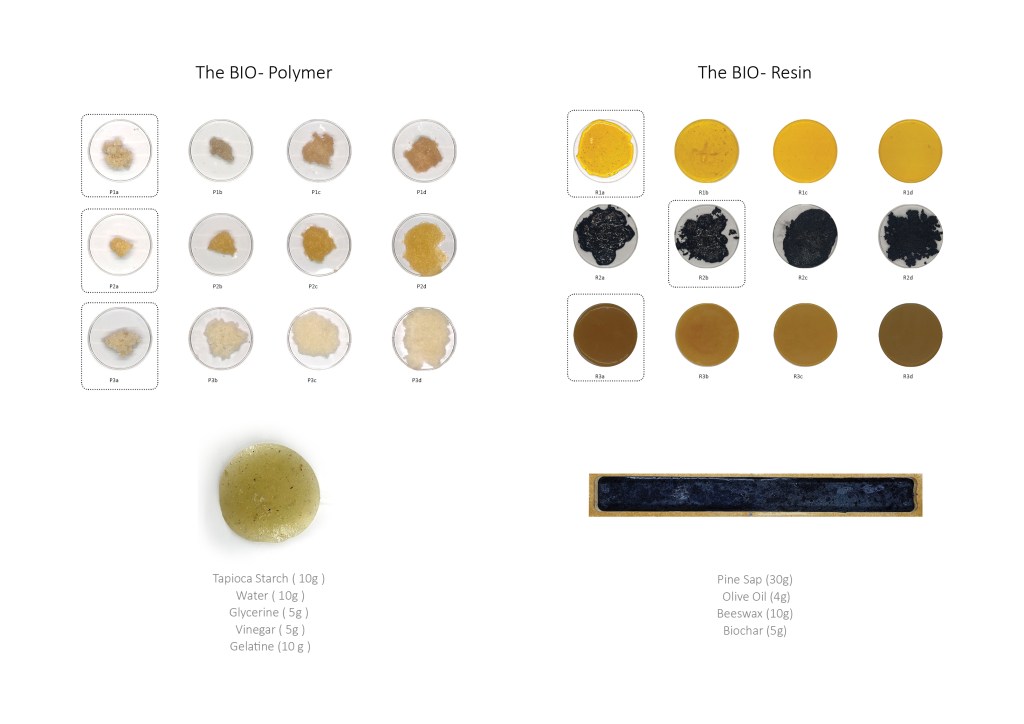

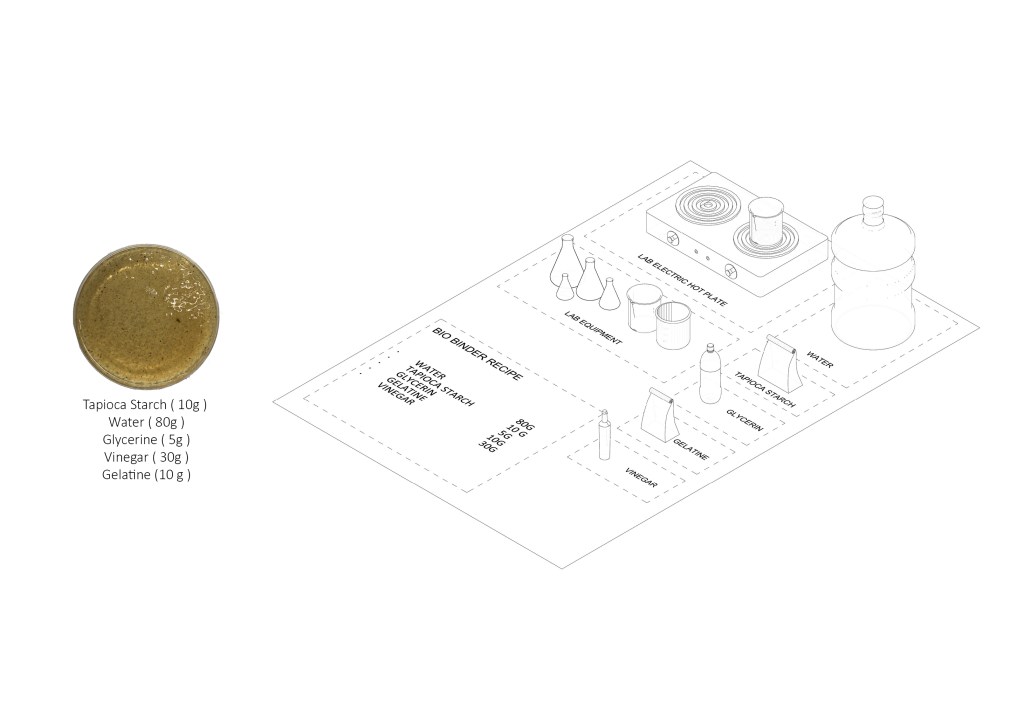

Bio Binder

Our material system demands the need of a binding agent. Bio-Binder would enhance our material system making it completely natural.

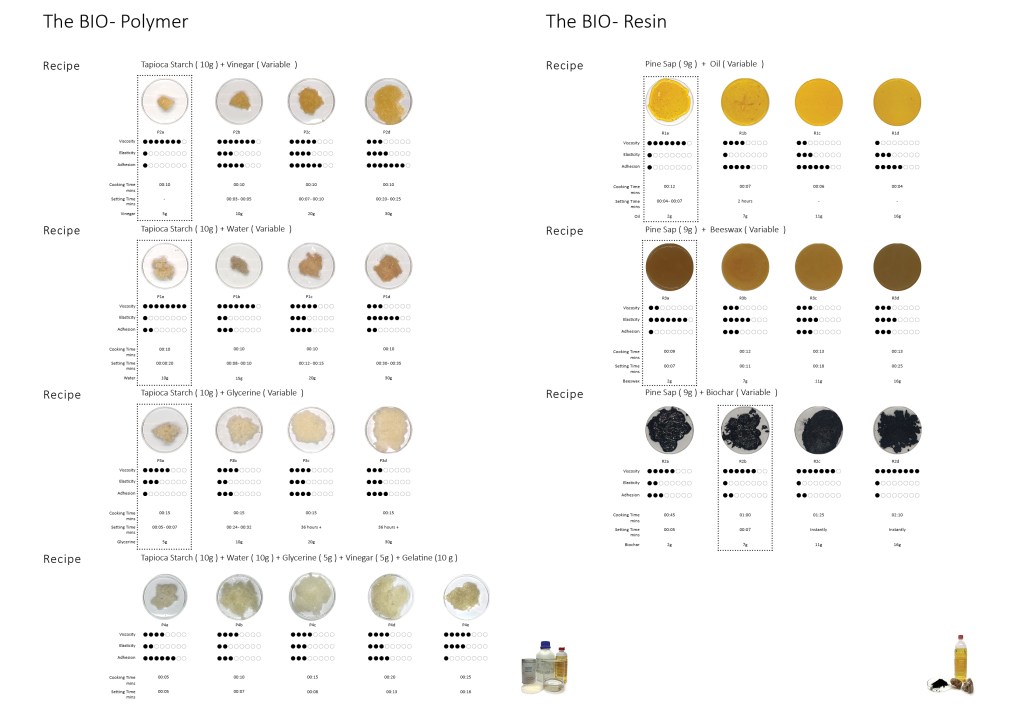

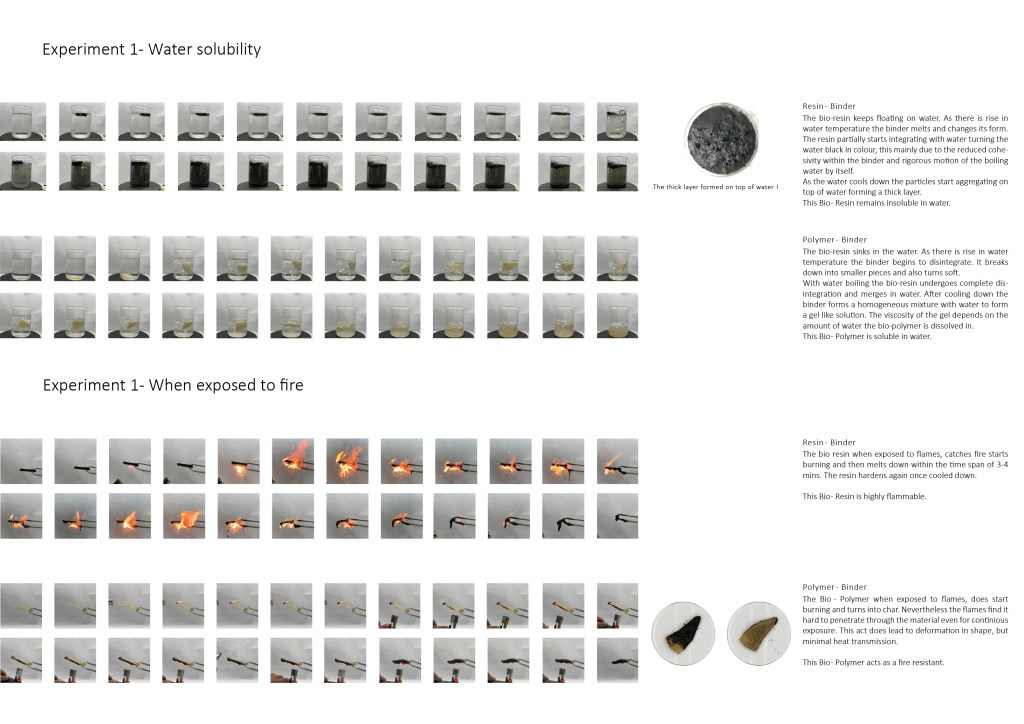

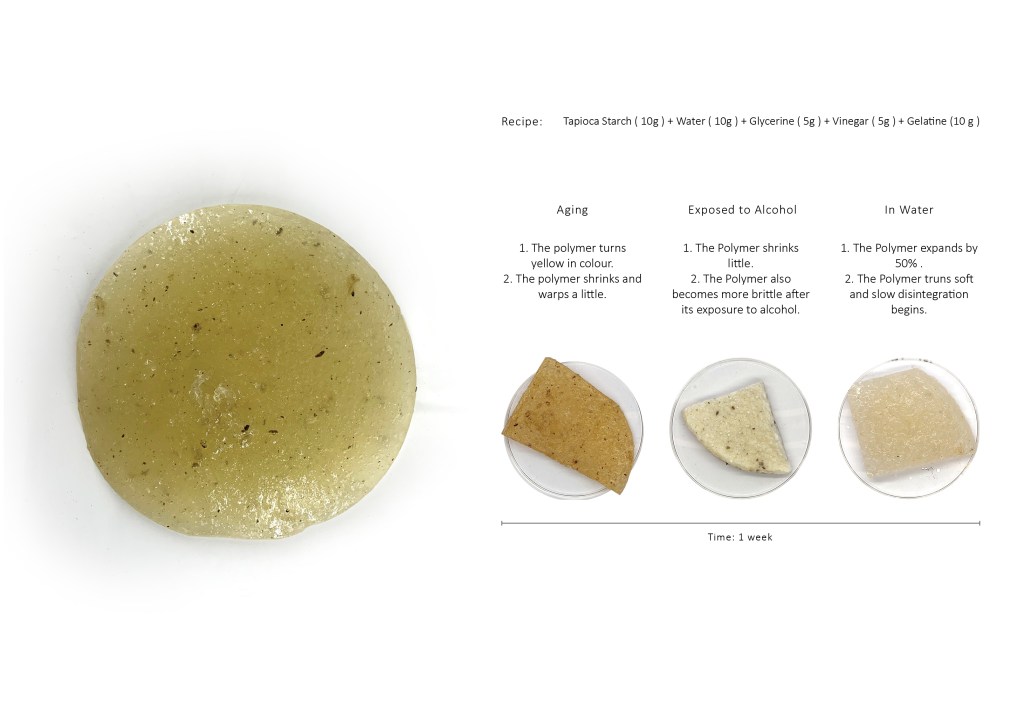

The two recipes that we worked on were based on the research done for the E-coir project ,Bartlett and the other one was for the Nomadic Pavilion, a research executed at IAAC. Each of the recipes were tested for their potentials. The pine resin failed when exposed to heat. On the contrary the Bio-Polymer responded interestingly well when exposed both to heat and water solubility tests. We worked on creating multiple iterations of the bio polymer by varying the proportions of its ingredients to narrow down to the desired consistency of the binder in order to maintain its strength and the ability of spraying.

Binder Cooking recipes

Bio-Binder Final Recipe

Material experiments

Fibers + Binder

Technique

The Shelter

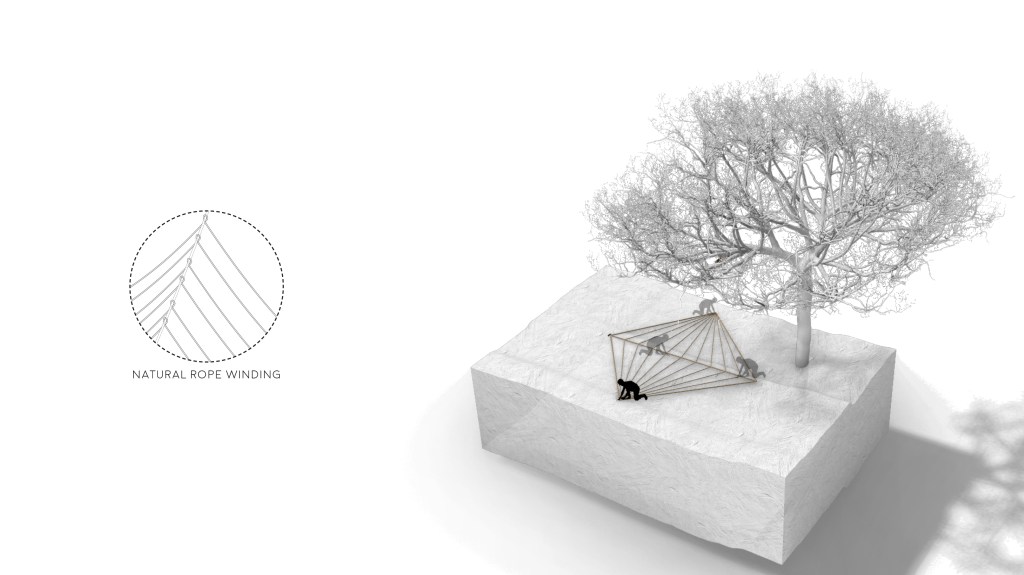

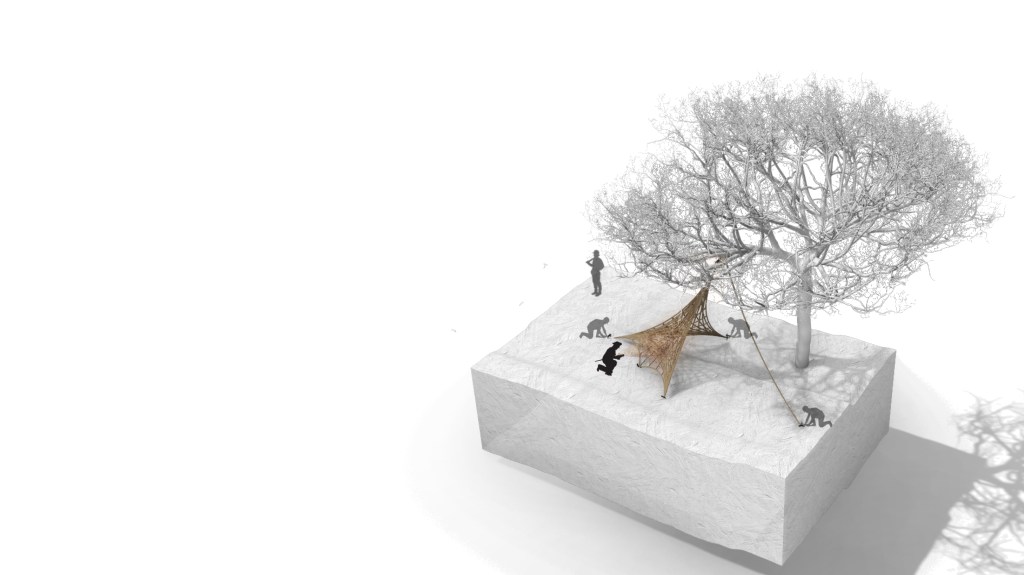

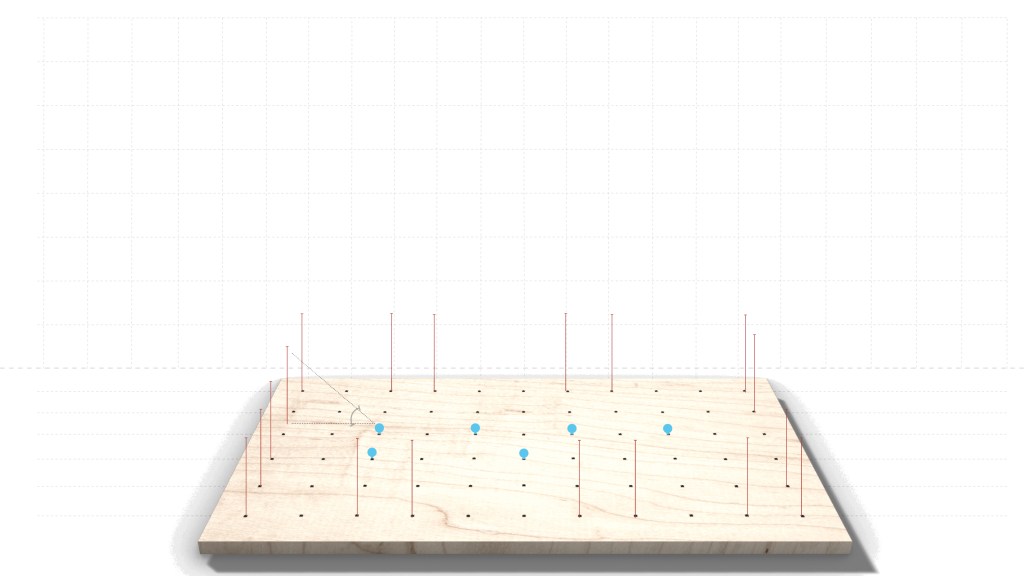

Temporary Shelter in unknown landscape | Human Weaving sub structure, Human Spraying

Augmented Reality Application in this project comes to help the human in the construction process.

We aim to use AR application in two situations. First situation is where the human needs to knit the sup-structure for spraying fibers and bio-binder, in this case AR application will show step by step how to knit. From the first step where/how to start until the end. The second situation is where the human needs to spray the fiber and bio-binder composite. We aim to have a real-time data processing and scanning of the sprayed parts, to analyze the thickness and the transparency of the sprayed material. In this case the human will know if any part needs more spraying.

Construction Process

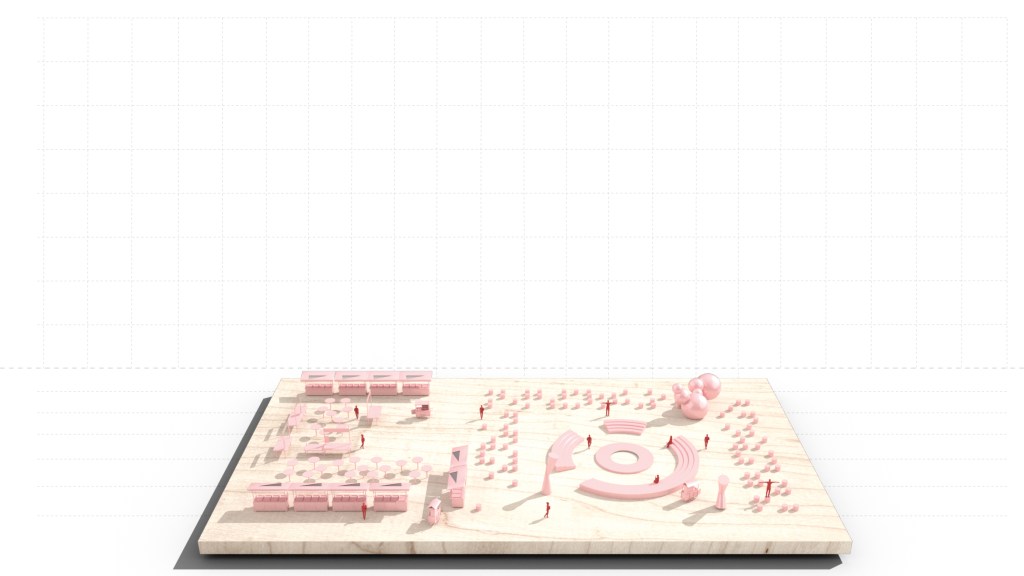

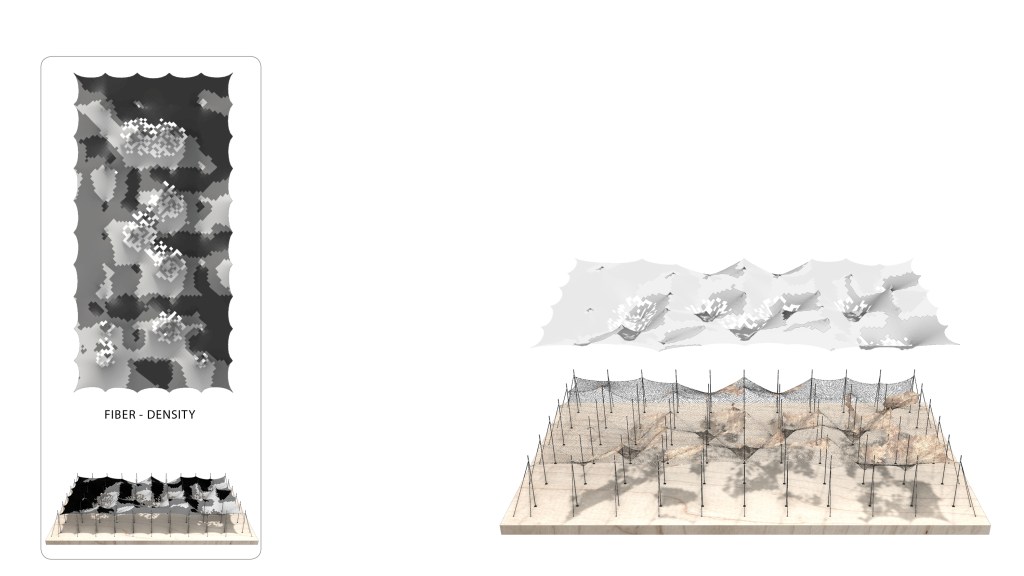

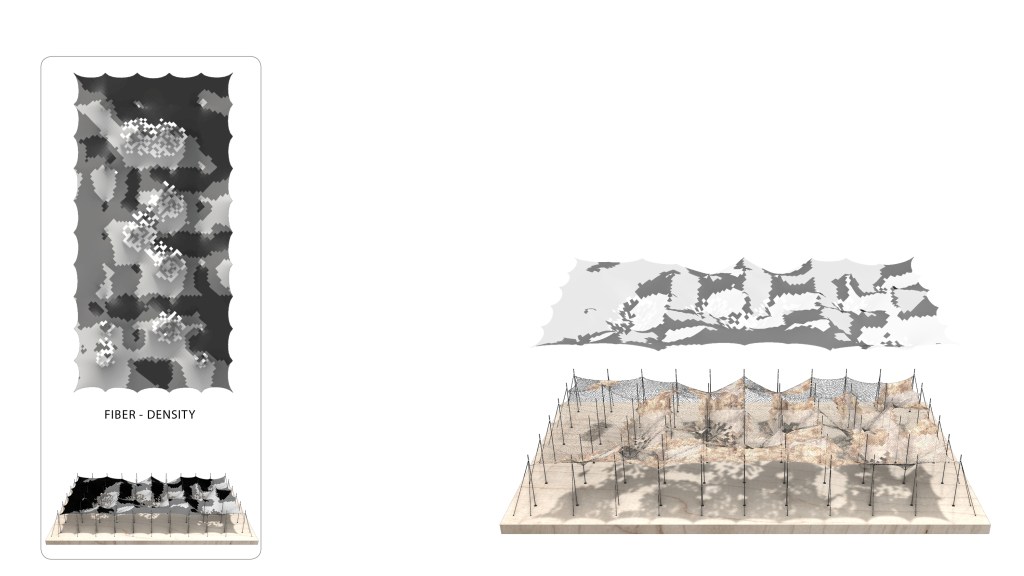

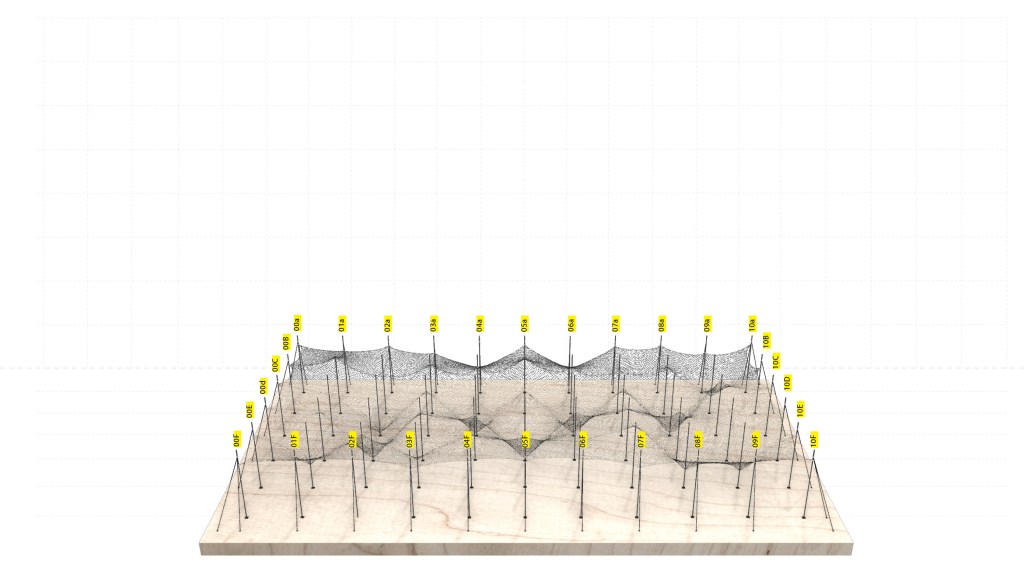

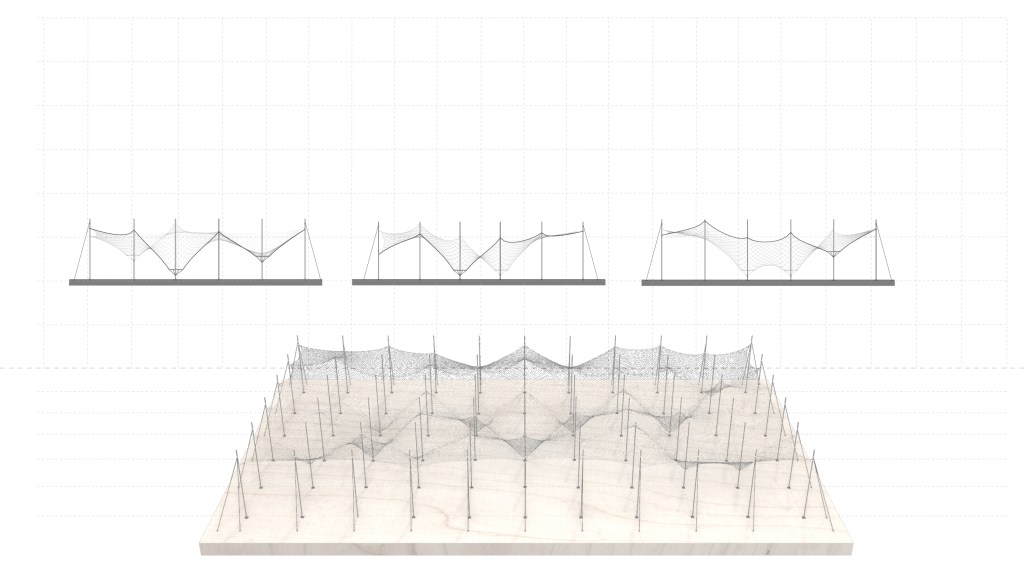

Temporary Public – Pre-Fabricated substructure

Human + MR collaboration for substructure installation – Agent Drone Spraying

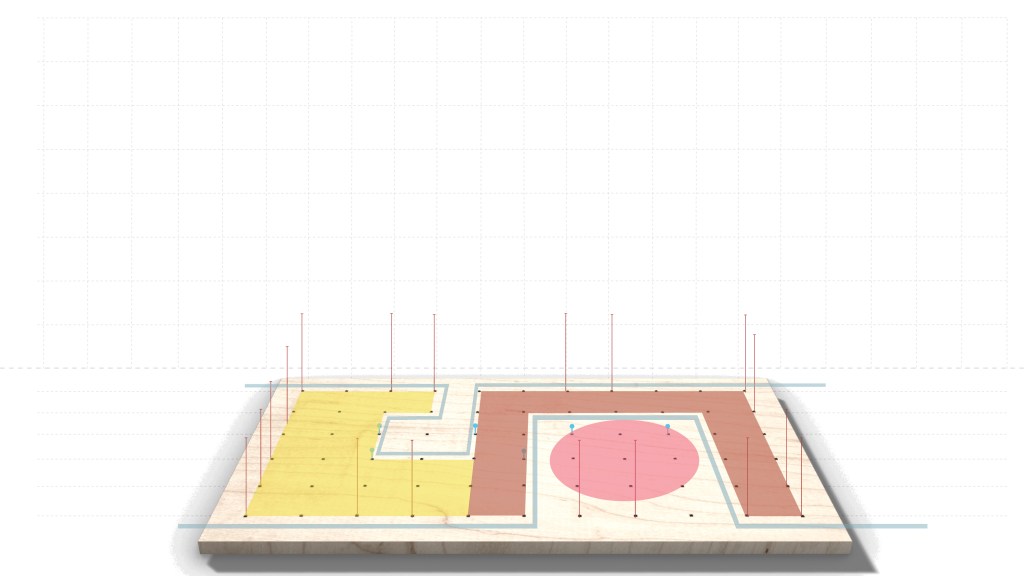

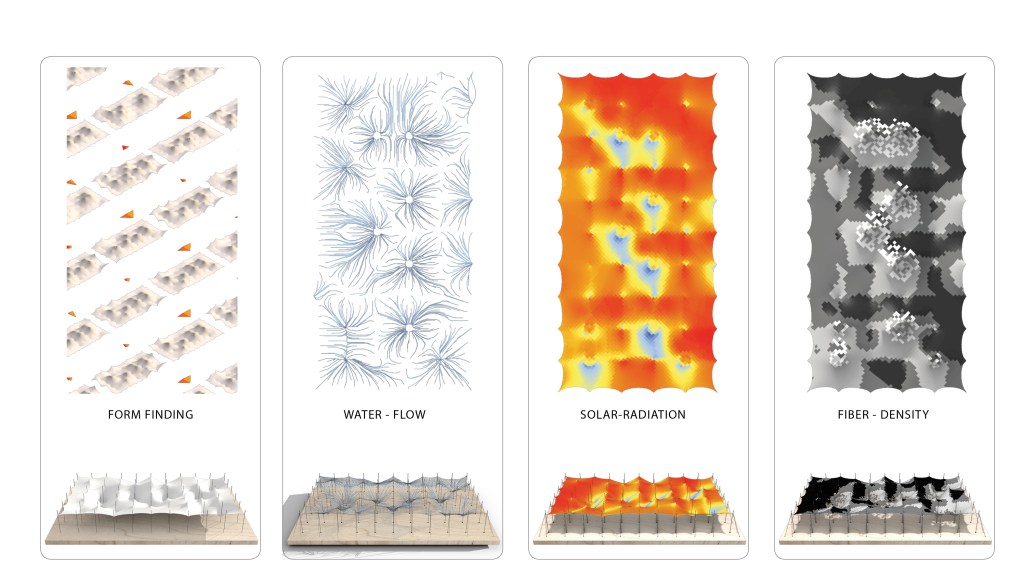

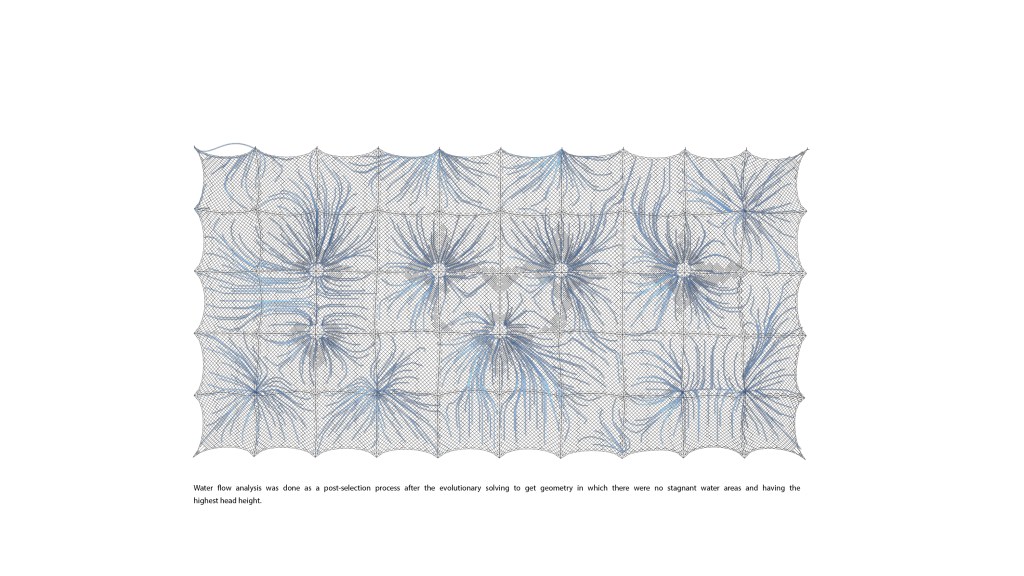

The form was derived through wallacei as an evolutionary solver with parameters given to increase the maximum distance between the program points, the maximum distance between high points and low points, Have the maximum height for the remaining points, and to increase the slope to the maximum within the mesh to have easy water runoff.

Construction Process

One more thing!

Life – After?

Team: Nareh Khaloian, Saurabh Singla, Aditya Mandlik, Akshay Mhamunkar, Areti Markopoulou, David Andrés León, Raimund Krenmüller, Nikol Kirova